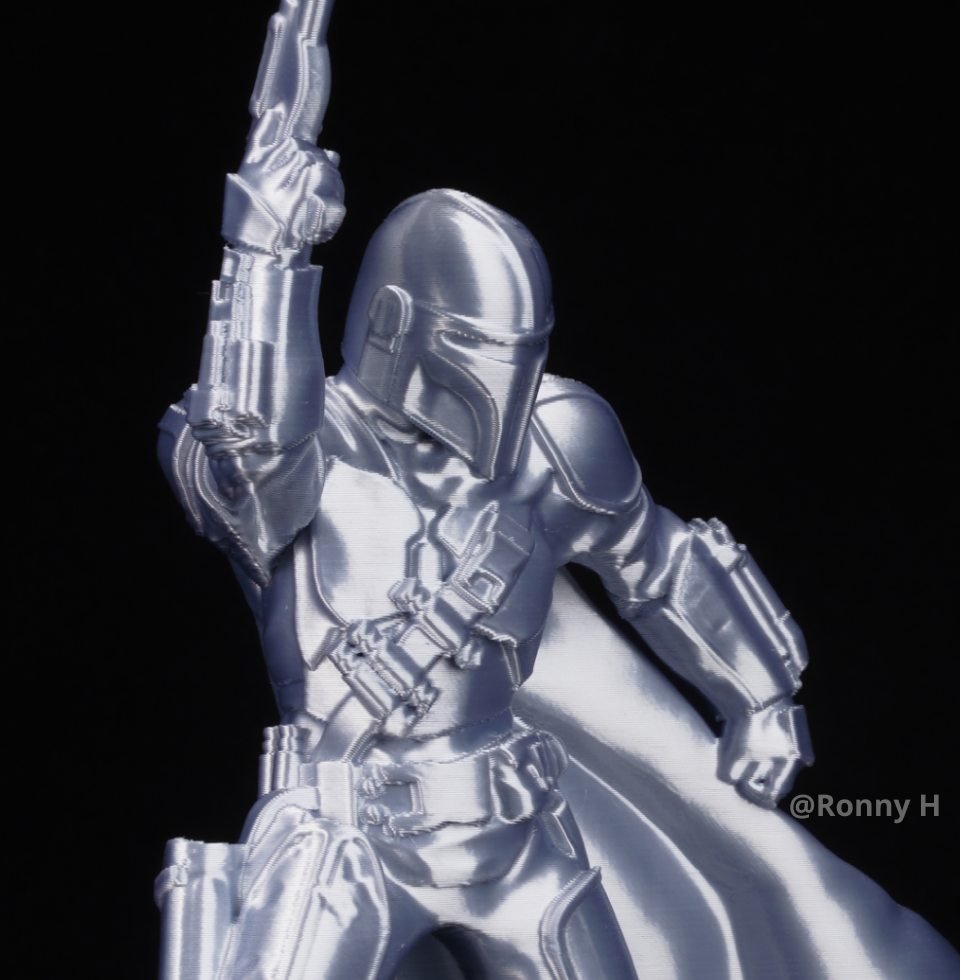

Bambu PLA Silk offers a silk-like and high-glossy that adds a luxury appearance to your prints while retaining PLA's ease of use. Different with other silk filaments, Bambu PLA Silk was toughened and demonstrates greater resistance to breakage when using AMS printing. It's ideal for decorations, artistic projects, and 3D character models or any parts where you want it shinier.

Bambu PLA Silk brings a silk-like appearance and long-lasting high gloss to your 3D prints, transforming models into stunning art.

Silky appearance shining glow

PLA Matte VS PLA Silk

Bambu PLA Silk is ideal for decorations, artistic projects, and 3D character models or any parts where you want it shinier.

Compared with regular PLA Silk, Bambu PLA Silk was toughened and demonstrates greater resistance to breakage when using AMS printing.

The appearance gloss of the model printed by Silk material can be controlled by printing temperature and speed. To get glossier finishes, higher printing temperatures and/or lower speeds are recommended.

Recommended settings: nozzle temperature: 230 - 240 °C, outer wall speed: 30 - 60 mm/s

| Color | Hex Code | Display |

| White | #FFFFFF | |

| Silver | #EAECEB | |

| Pink | #EEB1C1 | |

| Green | #4CE4A0 | |

| Gold | #E5B03D | |

| Blue | #147BD1 | |

| Purple | #854CE4 | |

| Copper | #5E4B3C |

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

| Recommended | Not Recommended | |

| Build Plate | Cool Plate, High Temperature Plate or Textured PEI Plate | Engineering Plate |

| Hotend | Hotend with Hardened Steel Nozzle (0.4 mm) Hotend with Stainless Steel Nozzle (0.2 mm, 0.4 mm) | Hotend with Hardened Steel Nozzle (0.6 mm, 0.8 mm) |

| Glue | Liquid Glue / Glue Stick | / |

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 55 °C,8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 210 - 240 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 250 mm/s |

| Physical Properties | |

| Density | 1.32 g/cm³ |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature | 53 °C |

| Melting Temperature | 152 °C |

| Melt Index | 20.5 ± 1.2 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 27 ± 4 MPa |

| Breaking Elongation Rate | 3.5 ± 0.6 % |

| Bending Modulus | 2370 ± 150 MPa |

| Bending Strength | 66 ± 4 MPa |

| Impact Strength | 24.5 ± 1.7 kJ/m² |

• Drying conditions: 55℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI.